The other day I got a bunny, so did my roommates. They needed a place to chillax and do whatever rabbits do like poop and run away from anything that moves or makes sound (supposedly they'll get more relaxed within the week), so I got some short pen fencing from [Giant hardware emporium] and some 2x2 poles and made a pen.

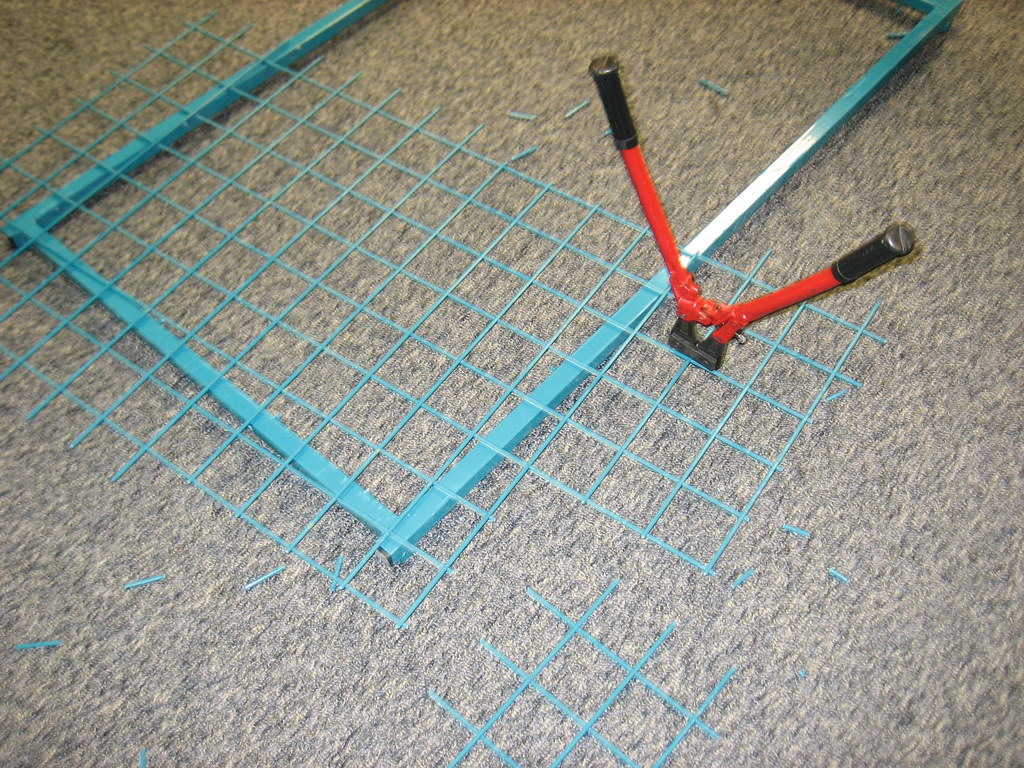

With a 50ft section of fence I decided to make each side 12' long, which leaves a little extra for future patches or mess-ups during making it. I cut the poles about 1 1/2' longer than the height of the fencing, then hammered them into the ground in a square shape. I used some baling wire to hold the first end to one of the poles and brought it around each corner, trying to make sure the fencing stayed as taut as possible and bringing the bends to a square corner at the corners. Next I hammered 1' stakes into the ground at an angle to the poles, drilled holes in the tops of the stakes and poles, then tied lines through each pole down to the stake as tightly as I could to prevent the poles from sagging inward. I also hammered the stakes down flush with the ground to tighten them up some more, and help mitigate the trip hazard.

To give them some shade and cover I took a couple of metal cans and some paneling to make a lean-to for them. All seemed pretty well the first couple days and we got comfortable letting them hang out on

their own for decent amounts of time, but the more skittish of the two (Bonnie) managed to push her way under the mesh and made a break for the woods

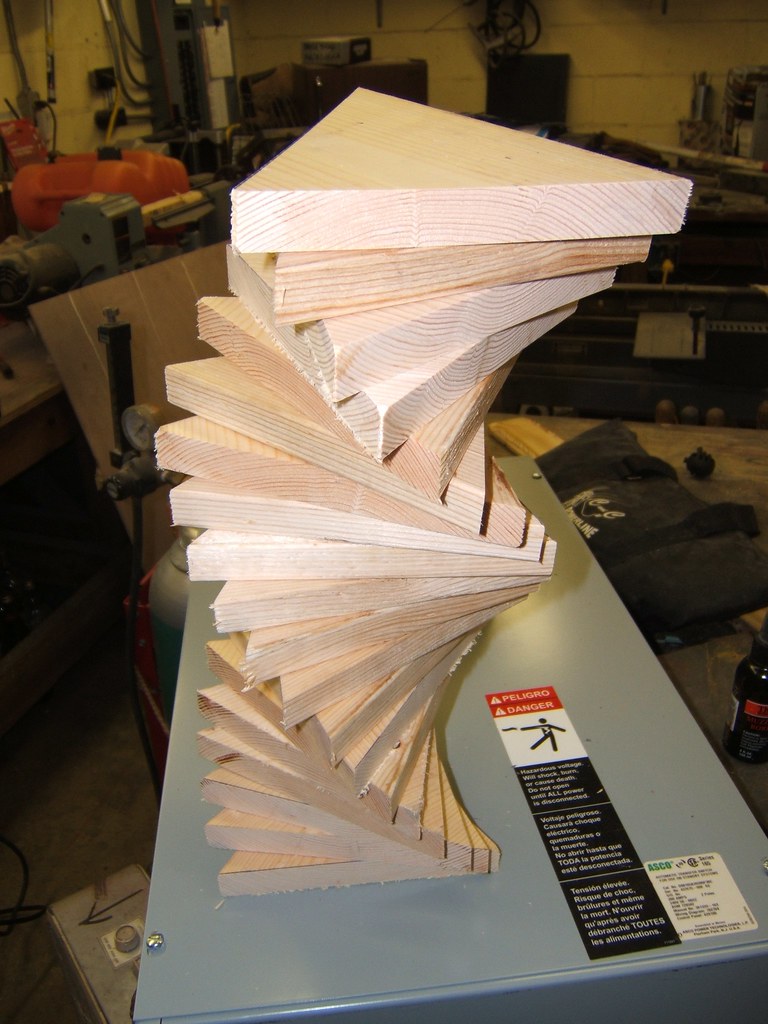

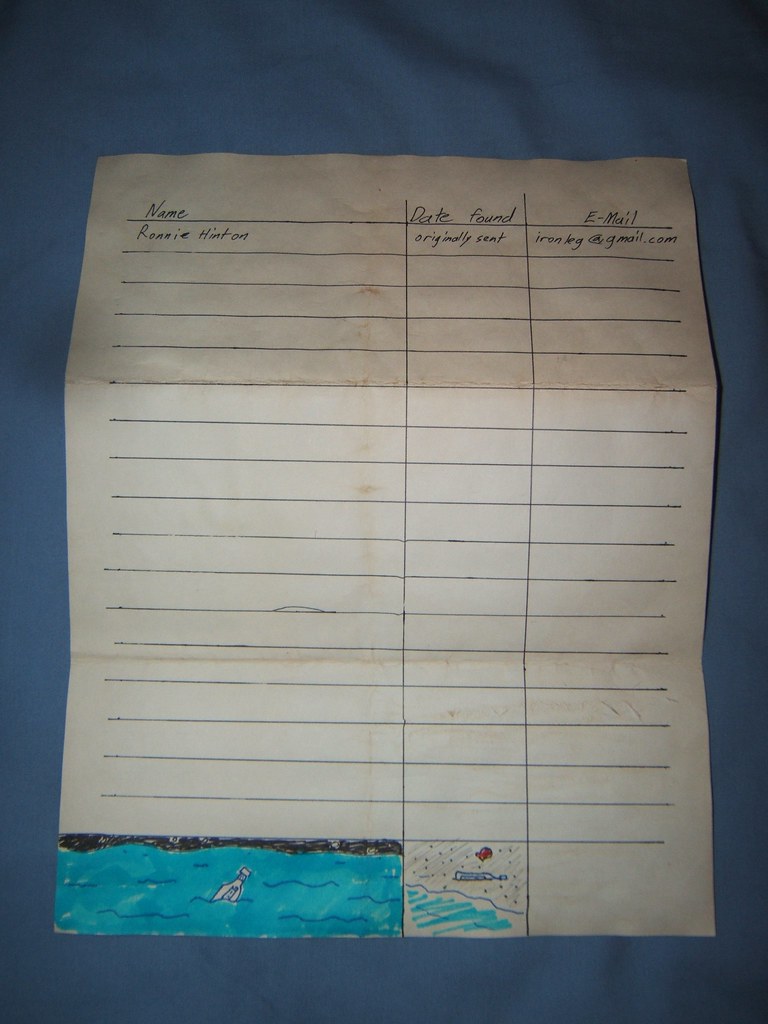

their own for decent amounts of time, but the more skittish of the two (Bonnie) managed to push her way under the mesh and made a break for the woods when we tried to catch her. After an all-day hunt, some close calls, and a couple of days waiting for her to find her way into a trap it appears she's gone for good. The wooden box shown is my less-than-stellar trap. Maybe I didn't bait it properly. I didn't even catch a squirrel or raccoon.

when we tried to catch her. After an all-day hunt, some close calls, and a couple of days waiting for her to find her way into a trap it appears she's gone for good. The wooden box shown is my less-than-stellar trap. Maybe I didn't bait it properly. I didn't even catch a squirrel or raccoon.I improved the pen with some metal hooks to keep the bottom tight to the ground, but the other rabbit (Dyna) also made an escape attempt; I assume by climbing over a corner. Between myself an my neighbor (thanks Mitch!) I got her back by tossing a blanket over her. My friends Mike and Sabrina got us a new rabbit I've dubbed Trillian and she and Dyna are currently making noise in the kitchen. They only get to go into the pen when there's someone around to make sure they don't cause trouble or make a break for it.

When we first got Trill she Dyna didn't take too kindly to her presence, so I had to

make a separate cage for Trill. I cut some pieces of hardware cloth to about the same size as Dyna's cage, made a paneling and 2x2 base for it, and zip tied the whole thing together. It's not as good as a store-bought cage since she can toss bedding out pretty easy, but it's still nice and she won't need it forever since they'll eventually bond well enough to share a cage.

make a separate cage for Trill. I cut some pieces of hardware cloth to about the same size as Dyna's cage, made a paneling and 2x2 base for it, and zip tied the whole thing together. It's not as good as a store-bought cage since she can toss bedding out pretty easy, but it's still nice and she won't need it forever since they'll eventually bond well enough to share a cage.When they're in the house they need to stay in the kitchen so they can do as they like without the risk of pooping or chewing on things they shouldn't (or which our landlord wouldn't appreciate). To this end I made a couple of bunny gates for the two entryways to the kitchen. One is made from our good friends pre-finished hardwood flooring and 2x2s. That gate is just a couple 2x2s of the same height as the pen with planks of flooring nailed to it with gaps just smaller than the head of a small rabbit. The other is a baby gate Mitch was nice enough to pass my way with an added piece on either side to make it fit the wider of the two entries.

What I've learned is that rabbits need you to either spend lots of money on them to keep them happy and safe or they prompt lots of making things to do those things.